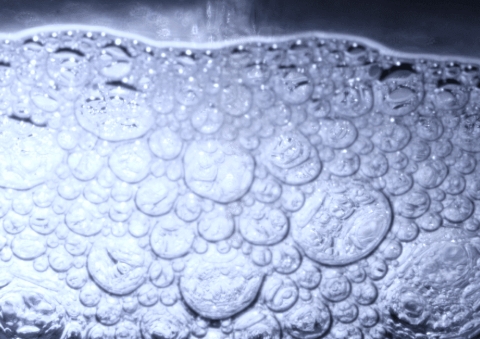

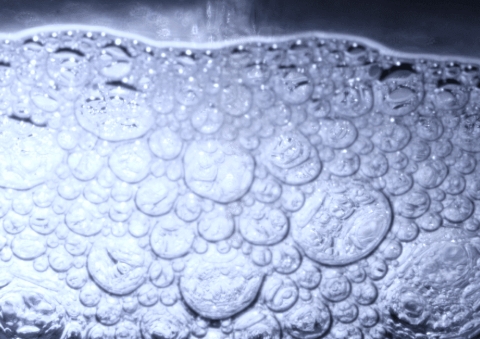

In the constant pursuit of cost reduction, it's tempting to choose the cheapest solution, especially when using auxiliary chemicals like defoamers. However, these short-term savings can become a long-term nightmare, silently compromising your product quality, damaging your equipment, and increasing your operating costs. Choosing a cheap or chemically incompatible defoamer is a gamble, with risks far greater than the initial price.

Here's a detailed look at the long-term and far-reaching consequences of using inferior defoamers.

1. Compromised Product Quality and Purity

This is the most immediate and devastating consequence. A defoamer not precisely formulated for your specific process can lead to a range of quality issues:

- Fisheyes and Surface Defects: Poorly emulsified defoamers can separate and create unsightly spots, pits, or blemishes in coatings, paints, films, and adhesives, leading to significant scrap.

- Degraded Adhesion and Performance: Incompatible components can migrate to interfaces, forming weak boundary layers that affect the glue line or adhesion of the coating to the substrate. Contamination and Odor: Low-quality defoamers often contain impurities or volatile components that can contaminate batches of food, pharmaceuticals, or sensitive chemicals, leading to off-flavors, taste issues, and even safety failures.

2. The Hidden Killer: Equipment Damage and Downtime

The hidden costs of equipment wear and tear often go unnoticed until it's too late.

- Fouling and Deposits: Unstable defoamers break down and form stubborn, sticky deposits on heat exchangers, sensors, filters, and tank walls. These deposits reduce heat transfer efficiency, clog nozzles, and require frequent, costly downtime for aggressive cleaning.

- Corrosion: Substandard defoamers may contain corrosive salts or chlorides that slowly attack pipes, reactors, and tanks. This leads to pitting, leaks, and ultimately premature equipment failure, requiring expensive repairs or replacement.

3. The Vicious Cycle of Inefficiency

Ironically, cheap defoamers often cost more in the long run.

- Higher dosage, lower performance: You get what you pay for. Ineffective defoamers require significantly increased dosage to achieve minimal foam control. This increases your direct chemical consumption and unit costs, offsetting any initial savings.

- Process disruptions: Persistent foaming issues can lead to overflows, reduced tank capacity, and slower processing speeds. These disruptions can create bottlenecks, delay production schedules, and increase labor costs for ongoing monitoring and intervention.

4. Invisible Contamination and Microbial Growth

In aqueous systems such as wastewater treatment or pulp and paper production, certain organic defoamers can serve as a food source for bacteria and fungi. This can promote:

- Slime formation: Biofilms can clog the system and reduce product quality.

- Increased biocide requirements: You'll need to use more biocide to control microbial growth stimulated by the defoamer itself, adding cost and complexity.

5. Reputational Damage and Liability

When your end product is inconsistent, defective, or contaminated, your reputation is the ultimate casualty. Years of customer trust built can be destroyed by a single batch of inferior additive. In regulated industries like food or pharmaceuticals, this can also lead to regulatory non-compliance, product recalls, and significant legal liability.

Our defoamers are:

- Engineered: Tailored to specific industries and applications, ensuring perfect compatibility.

- Efficient: Achieve superior, long-lasting foam control at low dosages.

- Reliable and stable: Formulated to prevent separation and ensure consistent performance from batch to batch.

- Safe and compliant: Meet stringent requirements across industries, including food-grade and environmental certifications.

Don't let short-sighted defoamer decisions burden your business in the long term. Choose a partner who understands the science and the stakes.

Contact us today for a consultation. Let us help you protect your processes, products, and profitability over the long term.