What Are You Looking For?

Is there a lot of foam in the desulfurization process?

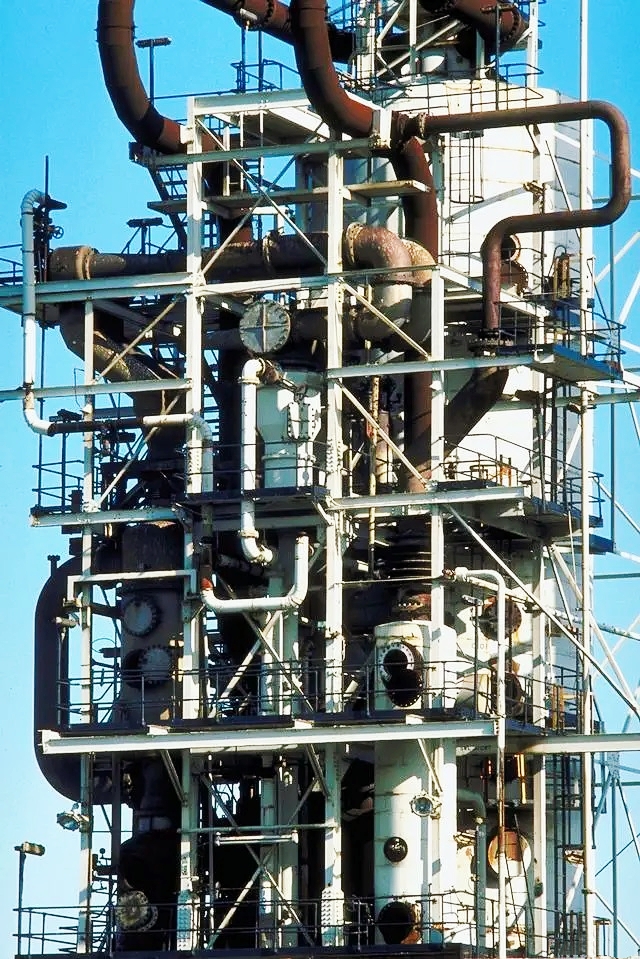

Nov 18, 2024Excessive foam is a common and thorny problem in the industrial desulfurization process. Large amounts of foam not only affect desulfurization efficiency but may also lead to a series of subsequent operational difficulties, and desulfurization defoamers play a vital role in solving this problem.

There are many reasons for the generation of foam in the desulfurization process. On the one hand, the chemical components in the desulfurizer may produce surfactants during the reaction process, which will reduce the surface tension of the liquid and promote the formation of foam. On the other hand, operational factors such as gas entrainment and excessive stirring intensity during the desulfurization process will also aggravate foam generation. Excessive foam will occupy the effective space of the reaction equipment and reduce the gas-liquid contact area, so that the desulfurization reaction cannot be fully carried out and the desulfurization effect will be reduced. Moreover, the foam may overflow the equipment, causing material loss and environmental pollution.

The reason why desulfurization defoamers can become a key solution is because of their special mechanism of action. Desulfurization defoamers have low surface tension and can spread quickly on the surface of the foam. When it contacts the foam, it will destroy the elastic membrane structure of the foam, making the foam liquid film thinner and eventually rupture. At the same time, high-quality desulfurization defoamers also have good foam suppression performance, which can prevent new foam from being generated at the source.

When selecting a desulfurization defoamer, multiple factors need to be considered. First, it is necessary to ensure that the defoamer has good compatibility with the desulfurization system and will not react chemically with the desulfurizer or other process media to avoid affecting the normal progress of the desulfurization reaction. Secondly, the defoaming speed and foam suppression time of the defoamer are important performance indicators. Fast defoaming speed can solve the foam problem in time, while long-term foam suppression ability can maintain the stability of the desulfurization process. In addition, the environmental protection of the defoamer needs to be considered, and non-toxic and biodegradable products should be selected as much as possible to reduce the negative impact on the environment.

In actual use, the correct addition method and dosage are also crucial. Usually, the addition amount of the desulfurization defoamer can be accurately controlled by installing a special addition device, such as a metering pump, at an appropriate location in the desulfurization system. Too little addition may not effectively eliminate the foam, while too much addition may lead to increased costs or residues in the system, affecting subsequent process operations.

In short, the foam problem in the desulfurization process seriously affects production, but through the reasonable selection and use of desulfurization defoaming agents, the foam can be effectively controlled, the desulfurization efficiency can be improved, and the stable operation of the desulfurization process can be guaranteed, thereby achieving better environmental and economic benefits.

Tags :