What Are You Looking For?

The Science of Defoamers in PCB Cleaning: Why Foam Control Matters

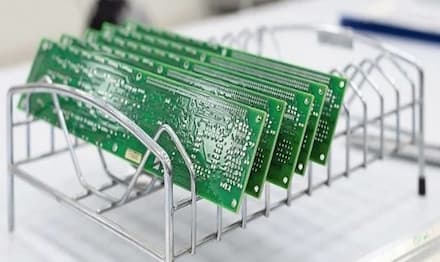

Apr 03, 2025Printed Circuit Boards (PCBs) are the backbone of modern electronics, but their manufacturing and maintenance require meticulous precision. One often-overlooked step in this process is cleaning, where residues, flux, and contaminants are removed to ensure optimal performance. However, a common challenge during PCB cleaning is foam formation, which can compromise efficiency and quality. Enter defoamers—specialized additives designed to tackle foam-related issues. This article dives into the science behind defoamers, their role in PCB cleaning, and how they contribute to reliable electronics manufacturing.

Why Foam is a Problem in PCB Cleaning

Foam may seem harmless, but in industrial cleaning processes, it poses significant risks:

1. Reduced Cleaning Efficiency: Foam traps air, preventing cleaning agents from reaching contaminants.

2. Equipment Damage: Excessive foam can overflow tanks, damaging machinery and sensors.

3. Inconsistent Results: Residual foam may leave streaks or deposits on PCBs, affecting conductivity.

In high-pressure spray or ultrasonic cleaning systems, surfactants in cleaning solutions generate foam due to agitation. Without proper control, this foam becomes a liability.

How Defoamers Work: Breaking Down the Chemistry

Defoamers (or antifoaming agents) are formulated to destabilize foam bubbles. They typically contain three key components:

1. Active Agents: Hydrophobic particles (e.g., silica, waxes) pierce foam walls.

2. Carrier Fluids: Oils or solvents disperse active agents evenly.

3. Emulsifiers: Stabilize the mixture for consistent performance.

When added to a cleaning solution, defoamers target the air-liquid interface of bubbles. The hydrophobic particles disrupt the foam’s surface tension, causing bubbles to collapse rapidly.

Types of Defoamers for PCB Applications

Not all defoamers are created equal. Selecting the right type depends on the cleaning method and PCB material:

1. Silicone-Based Defoamers:

- Ideal for aggressive cleaning agents.

- Provide long-lasting foam control but require careful rinsing to avoid silicone residue.

2. Non-Silicone (Organic) Defoamers:

- Use mineral oils or polyglycols.

- Suitable for water-based cleaners and eco-friendly formulations.

3. Powdered Defoamers:

- Used in dry or low-moisture cleaning systems.

- Dissolve gradually for sustained action.

Key Considerations When Choosing a Defoamer

1. Compatibility: Ensure the defoamer doesn’t react with PCB materials or cleaning agents.

2. Temperature Stability: Must perform under varying thermal conditions (e.g., heated wash tanks).

3. Environmental Impact: Opt for biodegradable or low-VOC options to meet sustainability goals.

4. Regulatory Compliance: Verify adherence to standards like RoHS or REACH.

The Future of Defoamer Technology

Innovations in foam control are aligning with broader industry trends:

- Nanotechnology: Nanoparticle-enhanced defoamers offer precision and reduced dosage.

- Smart Defoamers: Sensors integrated into cleaning systems could adjust defoamer levels in real time.

- Green Chemistry: Plant-based surfactants and renewable carrier fluids are gaining traction.

Defoamers may be a small component in PCB manufacturing, but their impact is enormous. By ensuring foam-free cleaning processes, they safeguard product quality, reduce waste, and enhance operational efficiency. As electronics evolve, so too will the defoamers that keep their production lines running smoothly.

For engineers and manufacturers, understanding the science of foam control isn’t just about solving a nuisance—it’s about building reliability into every circuit board.