What Are You Looking For?

Composition, advantages and applications of emulsified silicone oil defoamer

Jun 12, 2025In industrial production and daily life, the foam problem has always been one of the problems that plague enterprises. The generation of foam may affect the reaction process, product quality or the operating efficiency of equipment. As an excellent defoamer, emulsified silicone oil defoamer has been widely used in many fields in recent years.

This article will analyze the composition, advantages, and applications of emulsified silicone oil defoamer in detail.

1. Composition of emulsified silicone oil defoamer

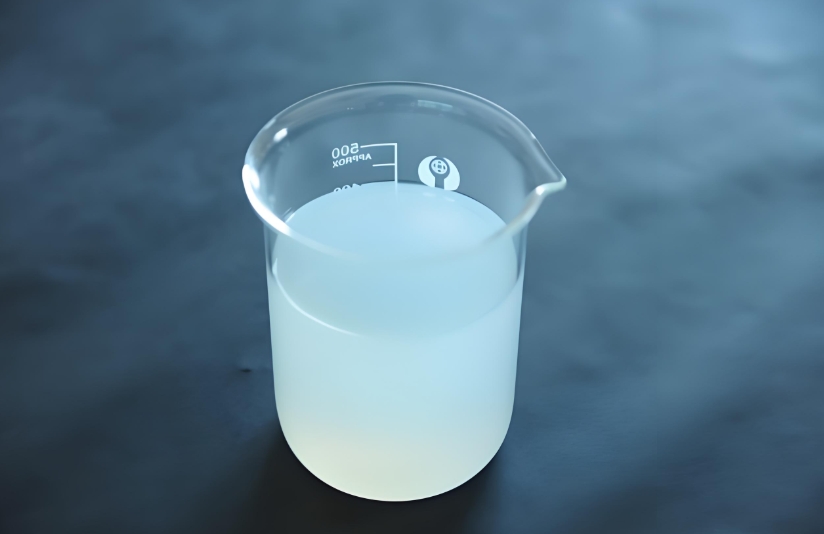

Emulsified silicone oil defoamer is mainly composed of emulsified silicone oil and emulsifier. It is an organic compound with excellent defoaming performance. Emulsified silicone oil is a liquid based on silicone oil with good hydrophobicity and thermal stability. Emulsifier can disperse silicone oil in water to form a stable emulsion, thereby increasing the solubility of defoamer in water and improving the defoaming effect.

2. Advantages of emulsified silicone oil defoamer

- Excellent defoaming performance: emulsified silicone oil defoamer can quickly eliminate foam in a short time without generating secondary foam.

- Good stability: It can still maintain good performance under harsh conditions such as high temperature and high humidity, and is not prone to stratification, precipitation and other phenomena.

- Non-toxic and harmless: Emulsified silicone oil defoamer does not contain harmful substances and is harmless to the environment.

- Wide applicability: Emulsified silicone oil defoamer is suitable for various aqueous media and high-demand industrial environments, and can meet the needs of different industries for defoamers.

3. Application scenarios of emulsified silicone oil defoamer

Emulsified silicone oil defoamer is widely used in various occasions where bubbles need to be controlled, such as:

- Chemical production: In chemical processes such as emulsion polymerization and resin synthesis, the generation of foam may affect the smooth progress of the reaction. Emulsified silicone oil defoamer can effectively control the foam and ensure the stability of the reaction process and product quality.

- Textile industry: In the textile printing and dyeing process, emulsified silicone oil defoamer can eliminate bubbles on the surface of the fabric, avoid uneven printing and dyeing or quality problems caused by residual foam, and significantly improve the appearance of the product.

- Oil and gas industry: During drilling and oil production, emulsified silicone oil defoamers can reduce the damage of foam to equipment, ensure the smooth progress of the production process, and improve oil production efficiency.

In short, emulsified silicone oil defoamers provide strong guarantees for production efficiency and product quality with their excellent defoaming performance and strong stability. In the future, with the continuous advancement of industrial technology, the application prospects of emulsified silicone oil defoamers will be broader.