What Are You Looking For?

Defoaming Agent: A Vital Role in Circuit Board Cleaning

Apr 29, 2024Circuit boards generally refer to circuit boards. It can be called a printed circuit board or printed circuit board, and its English name is PCB. Its purpose is to make circuits miniaturized and intuitive, and it plays an important role in mass production of fixed circuits and optimizing the layout of electrical appliances. General circuit board materials are divided into rigid substrate materials and flexible substrate materials.

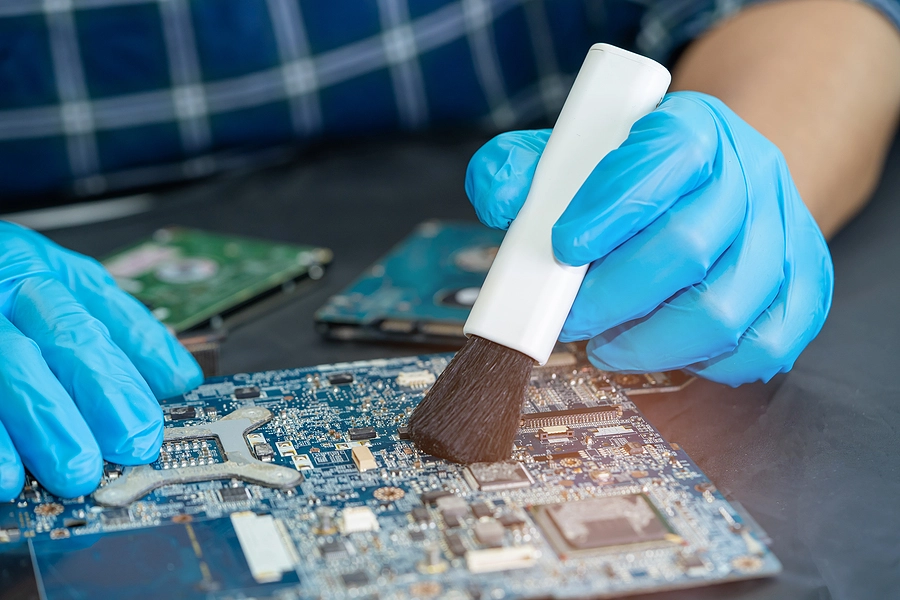

Defoaming agents play a vital role in circuit board cleaning.

Defoaming agents are used in circuit board substrate cleaning, circuit board water treatment, film removal, etching, development, and sewage treatment (the entire PCB process). Especially in the dry film process during the production of printed circuit boards, the unexposed dry film is removed through development. The dry film is photosensitive insulating resin, and the developer is sodium carbonate solvent. Due to the continuous dissolution of the dry film, the developer produces a certain amount of foam during the system circulation spray process. When foam reaches a certain level, it will affect the quality of development and cause inconvenience to production.

The main component of circuit board cleaning is specially modified polyether, which will not cause silicon spots to remain on the tank wall, making it easy to clean the equipment. It has excellent defoaming and anti-foaming properties. In addition, it also has high stability and water dispersion properties. It is specially designed for cleaning printed circuit boards and can be widely used in the development and stripping processes (the entire PCB process can be used). It will not affect the processing of circuit boards, has good water solubility, does not float oil, and has no residue.

How to use defoaming agent for circuit board cleaning:

1. How to use silicone defoamer for circuit board cleaning:

It can be added directly during the cleaning process, added to the foaming liquid after dilution with water, or added to the bath liquid in advance to achieve the effects of foam suppression and defoaming. When using it, the amount can be increased or decreased depending on the defoaming effect. The recommended amount is 0.1~0.3% of the total amount.

2. How to use polyether defoamer for circuit board cleaning:

It is best to add it before foaming. The amount of addition depends on the actual defoaming requirements. Usually the starting concentration is 0.3~0.5ml per liter of bath liquid. However, when the bath liquid is dissolved due to dry film or wet film, When reaching saturation, the amount of addition needs to be increased